An article to understand the breaking torque of the hose clamp

What is the hose clamp breaking torque? The breaking torque of a throat clamp refers to the torque value required…

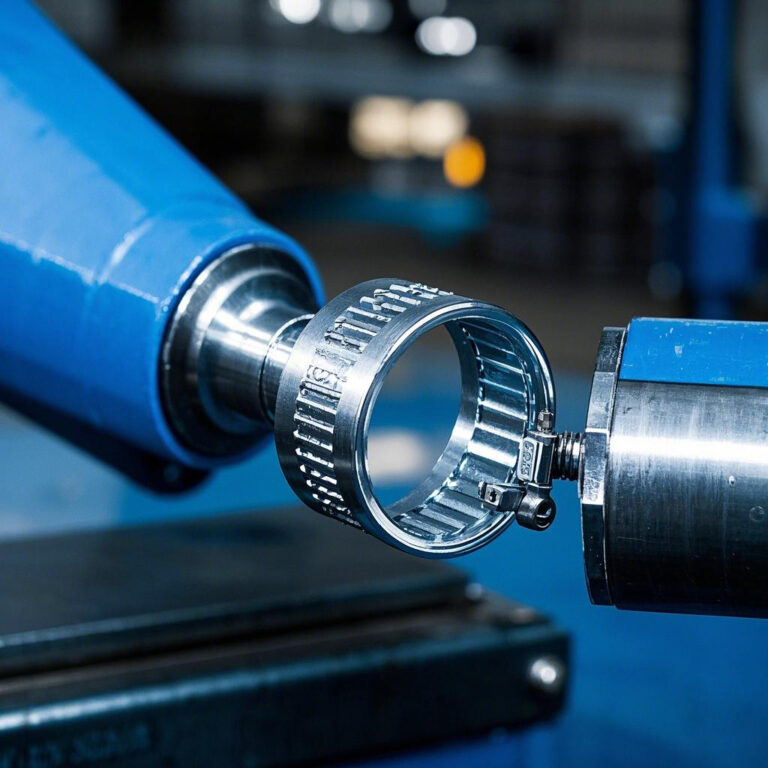

What is the hose clamp breaking torque?

The breaking torque of a throat clamp refers to the torque value required to break the throat clamp during a torsion test. It is a key indicator for measuring the mechanical strength and durability of the throat clamp, and reflects the ultimate ability of the throat clamp to withstand torsion. In simple terms, it is like testing how much twisting force a throat clamp can “withstand” at most, and it will break if it exceeds this force.

How to determine the breaking torque of the hose clamp?

Usually, professional torque testing equipment is used, such as a torque wrench and a torque meter. The hose clamp is installed on a specific test fixture to simulate the installation state in actual use, and then the torque is slowly applied through the torque wrench, and the torque value is recorded in real time by the torque meter. As the torque continues to increase, when the hose clamp breaks, the torque value at this time is recorded, which is the breaking torque of the hose clamp.

What factors affect the value of the throat clamp breaking torque?

1. Material: Different materials of throat hoops have different strengths and toughness, and their breaking torques are also very different. For example, stainless steel throat hoops usually have higher breaking torques than ordinary carbon steel throat hoops because stainless steel has better strength and corrosion resistance.

2. Size specifications: The diameter, thickness and other dimensional parameters of the throat hoop will affect its breaking torque. Generally speaking, the larger the size and the thicker the throat hoop, the greater the torque it can withstand, and the higher the breaking torque.

3. Manufacturing process: The processing accuracy and heat treatment process in the manufacturing process have a significant impact on the performance of the throat hoop. After good heat treatment, the throat hoop has a more uniform internal structure, higher strength, and a correspondingly higher breaking torque; if the manufacturing process is rough, defects may occur inside the throat hoop, reducing its breaking torque.

Keeping the breaking torque in mind will ensure functionality and safety in all of your applications.

Contact us for more information on our range of clamps.