Can you use hose clamps on exhaust

The exhaust pipe is an important part of internal combustion engine vehicles such as cars and sedans. Its main function…

The exhaust pipe is an important part of internal combustion engine vehicles such as cars and sedans. Its main function is to discharge the exhaust gas generated by fire outside the vehicle. The exhaust pipe is usually made of metal materials, so it is exposed to high temperature, high pressure and corrosive gases for a long time, and the requirements for its connection and sealing are very high. In some cases, the driver or maintenance personnel may consider using a hose clamp to fix or seal the connection part of their exhaust pipe. However, are hose clamps suitable for exhaust pipes? What problems may be encountered when using hose clamps? How to solve these problems? This article will discuss these topics in detail.

1. Basic characteristics of laryngoscope

Laryngoscope clamp is a common mechanical end, usually used to fix the connection between the hose and the hard pipe or joint. The main characteristics of the throat clamp include:

1. Material diversity: The throat clamp is usually made of stainless steel, carbon steel or plastic, with different corrosion resistance and strength.

2. Simple structure: The neck is usually composed of strip metal and screws, which are fixed to the upper part by tightening the screws to apply pressure.

3. Wide range of applications: The throat clamp can be used in many occasions such as water pipes, oil pipes, and gas pipes, and is suitable for the upper part of different pipe diameters.

Although the throat clamp performs well in many fields, whether it is suitable for exhaust pipes still needs further analysis.

2. Potential problems of using the top on the exhaust pipe

1. Performance issues in high temperature environment

The exhaust pipe will generate high temperature when working, especially the part close to the engine, the temperature may be as high as hundreds of degrees, and the material of the ordinary throat clamp may not be able to withstand such high temperature, resulting in the following problems:

Material softening or deformation: Some plastic or low-quality metal throat clamps may soften or deform at high temperatures and lose their function.

Loose screws: Too high may cause the screws to expand or loosen, thereby achieving the desired effect of reducing the throat clamp.

2. Impact of vibration and impact

The vehicle will generate continuous vibration and impact during driving, which puts higher requirements on the exhaust pipe connection part. The throat clamp may face the following challenges:

Insufficient retraction force: The retraction force of the top clamp may resist continuous vibration, resulting in loose connection.

Fatigue fracture: Long-term vibration may cause fatigue fracture of the metal belt or screw of the throat clamp.

3. Influence of corrosive gases

The exhaust gas discharged from the exhaust pipe contains weakening gases (such as purifiers, nitrides, etc.), which puts forward higher corrosion resistance requirements for the throat clamp material:

Rust problem: If the throat clamp material is not corrosion-resistant, it may rust in a short time, affecting its performance and service life.

Seal failure: Rust may cause uneven contact between the throat clamp and the exhaust pipe, thus affecting the sealing effect.

4. Special shapes and sizes of exhaust pipes

Exhaust pipes usually have complex shape features and increased pipe diameters, and the design of the throat clamp may not be able to adapt to these at all:

Size mismatch: The standard throat clamp may not be able to fully cover the connection part of the exhaust pipe, resulting in looseness.

Shape mismatch: The curved or special-shaped design of the exhaust pipe may prevent the throat clamp from applying pressure evenly, affecting the sealing effect.

3. Solutions and alternatives

Although there are many problems with using throat clamps on exhaust pipes, in certain specific cases, these problems can still be solved or circumvented through the following methods or alternatives.

1. Choose throat clamps made of high-temperature resistant materials

If throat clamps are used on exhaust pipes, throat clamps made of high-temperature resistant materials should be selected, such as:

Stainless steel throat clamps: Stainless steel has the characteristics of high temperature resistance and corrosion resistance, and is suitable for use on exhaust pipes.

High-temperature alloy throat clamps: Some special alloys can maintain stable performance under extremely high temperatures.

2. Enhanced anti-loosening measures

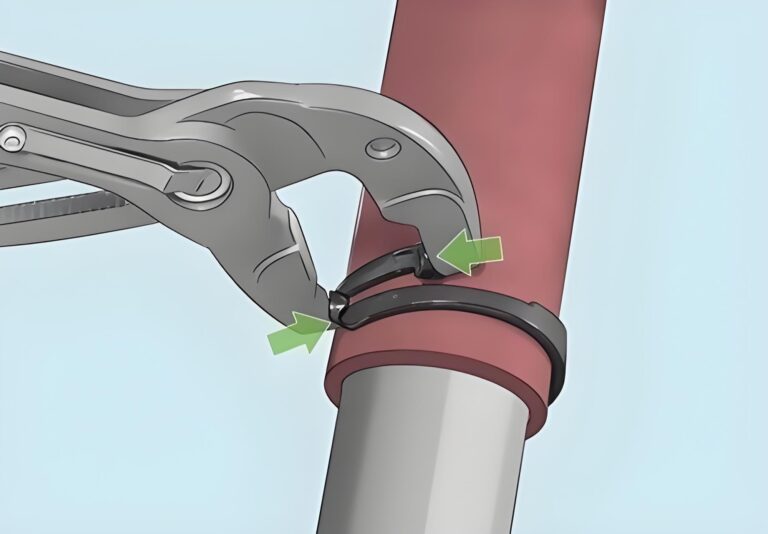

To prevent the throat neck from loosening under vibration, the following measures can be taken:

Use anti-loosening screws: Anti-loosening screws can keep it still under vibration.

Double throat clamp fixation: Use double throat clamps at key connections to increase support.

3. Use corrosion-resistant coatings

To improve the corrosion resistance of the throat clamp, its surface can be specially treated:

Transparent treatment: Transparent neck shoulders have good corrosion resistance.

Ceramic coating: Some ceramic coatings can protect the top clamp in high temperature and corrosive environments.

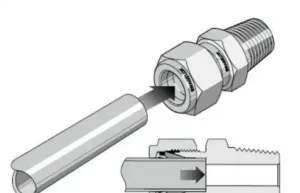

4. Custom hose clamps

For exhaust pipes with complex shapes or special sizes, please consider custom form clamps:

Custom size: Top clamps are made according to the diameter and shape of the exhaust pipe to ensure a perfect fit.

Strengthened design: Add reinforcement ribs to key parts of the throat neck to improve its anti-vibration and impact resistance.

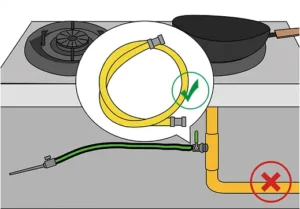

5. Use special exhaust pipe joints

In some cases, using a clamp on the top may not be the best choice. Consider using special exhaust pipe connectors, such as:

Flange connection: Flange connection has extremely high sealing and supporting force, suitable for high temperature and high pressure environments.

V-clamp: V-clamp can apply pressure evenly and is suitable for connecting special-shaped exhaust pipes.

4. Actual case analysis

Case 1: Repair of bracket exhaust pipe

A crane owner found a leak at the connection between the exhaust pipe and the muffler. Due to limited budget, he tried to use a stainless steel throat clamp for temporary repair. However, after a period of use, the throat clamp became loose in a high temperature and closed environment, resulting in leakage. Finally, the owner chose to use a special V-type card for repair, and the problem was completely solved.

Case 2: Wholesale of automobile foreign trade pipes

When a car fan was selling pipes, he tried to use a throat clamp to fix the newly added tail throat. Due to the increased diameter of the tail throat, the standard throat clamp could not completely cover the connection, resulting in poor sealing. After consulting professionals, he chose to customize and enlarge the stainless steel throat clamp and add anti-loosening measures, and finally successfully completed the restaurant.

The throat clamp used on the exhaust pipe is installable, but the appropriate material, size and design need to be selected according to the specific situation. Ordinary throat clamps may not perform well in high temperature, vibration and corrosion environments, so it is recommended to give priority to high temperature and corrosion resistant stainless steel throat clamps, or use special exhaust pipe connectors. In actual operation, the environment and connection requirements of the exhaust pipe should be fully evaluated to ensure the reliability and durability of the connection work.