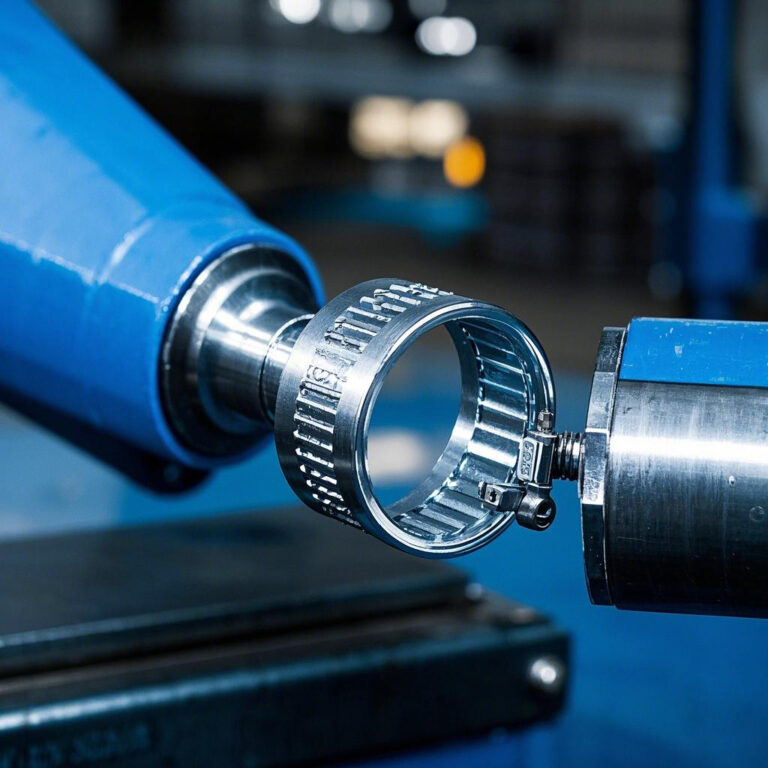

Hose clamp Residual torque indication

What is the residual torque indicator of a hose clamp? The residual torque indicator of hose clamp is a method…

What is the residual torque indicator of a hose clamp?

The residual torque indicator of hose clamp is a method used to judge whether the hose clamp is installed in place. It sets an indicator device on the hose clamp. When the preset torque is reached, the indicator device will change significantly (such as breaking, changing color, etc.), thus reminding the operator to stop tightening.

Why do we need residual torque indication?

Prevent over-tightening: Over-tightening can cause deformation and damage of the hose clamp, and even affect the sealing performance.

Ensure reliable sealing: Sufficient residual torque can ensure close contact between the hose clamp and the hose to prevent leakage.

Improve installation efficiency: Residual torque indication can simplify the installation process, reduce human judgment errors, and improve work efficiency.

What should I pay attention to when using residual torque indication?

Choose the appropriate torque value: The torque value should be determined according to the hose clamp specifications, hose material and working conditions.

Correct installation: Install the hose clamp and indicator device correctly according to the instructions.

Regular inspection: Regularly check whether the indicator device is intact and ensure that it works properly.

The hose clamp residual torque indicator is a simple and effective tool that can help us ensure that the hose clamp is installed in place, prevent leakage, and improve work efficiency. Choosing the appropriate indication method and using it correctly can effectively ensure the safety of equipment and personnel.

Contact us for more information on our range of clamps.