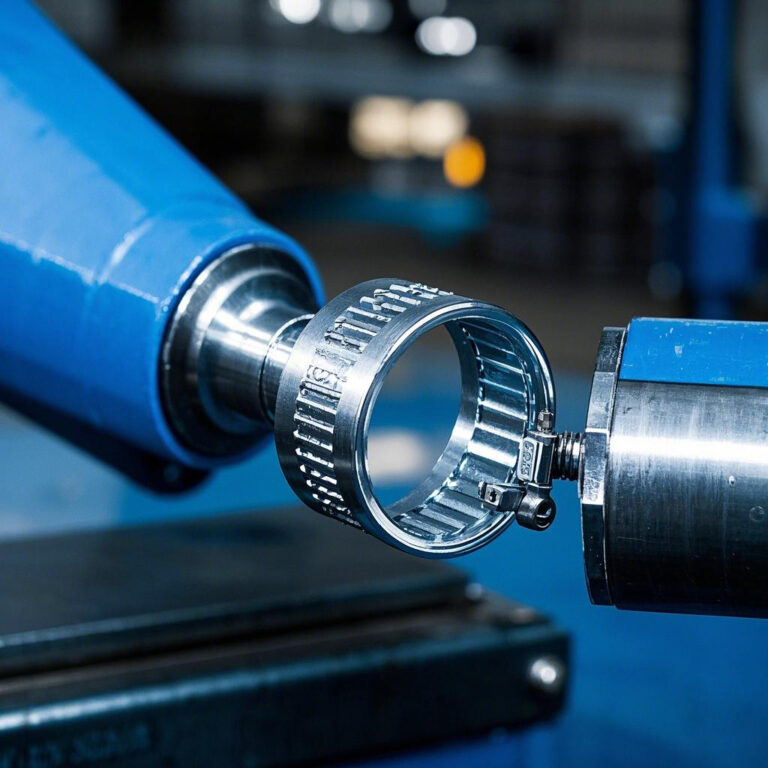

Hose clamp with wire stamping-Seikou hose clamp

Hose clamp wire stamping is an efficient and precise metal processing technology, which is widely used in the fields of…

Hose clamp wire stamping is an efficient and precise metal processing technology, which is widely used in the fields of automobiles, home appliances, construction, etc. This process continuously stamps metal strips through dies to form hose clamp products with specific shapes and functions.

Process flow:

1.Material preparation: Select metal strips that meet the requirements, such as stainless steel, carbon steel, etc., and perform necessary surface treatment.

2.Mold design: Design high-precision molds according to product requirements to ensure the accuracy of stamping size and shape.

3.Stamping forming: Feed the metal strip into the stamping machine and continuously stamp it through the mold to form the basic shape of the throat hoop.

4.Wire processing: During or after the stamping process, the throat hoop is processed with wires, such as punching, embossing, etc., to enhance its functionality.

5.Surface treatment: The formed throat hoop is surface treated, such as electroplating, spraying, etc., to improve its corrosion resistance and aesthetics.

6.Quality inspection: Strict quality inspection of the finished product to ensure that its dimensional accuracy, mechanical properties and appearance quality meet the standards.

Technical points:

Mold precision: High-precision molds are the key to ensuring product quality and require regular maintenance and upkeep.

Stamping parameters: Reasonably set parameters such as stamping speed and pressure to avoid material deformation or mold damage.

Wire processing: Wire processing requires precise control to ensure the functionality and assembly accuracy of the hose clamp.Surface treatment: Select the appropriate surface treatment process to improve the durability and aesthetics of the product.

The throat clamp wire stamping process has the advantages of high production efficiency and stable product quality, and is an indispensable and important technology in modern manufacturing.