How to effectively install hose clamps? Seikou will teach you

In pipeline connection, the installation quality of hose clamps directly affects the sealing and stability of the pipeline system. As…

In pipeline connection, the installation quality of hose clamps directly affects the sealing and stability of the pipeline system. As a leading brand in the industry, Seikou stainless steel hose clamps are popular for their multifunctional and corrosion-resistant properties. But how to install them correctly to give full play to their performance advantages? This article will disassemble the installation points for you in the form of questions and answers, answer common questions, and make the installation process more efficient and safer.

1. Preparation before installation: Choosing the right tools and accessories is the key

Q: What tools are needed to install Seikou hose clamps?

A: Basic tools include screwdrivers (for bolt-type hose clamps), wrenches (for torque adjustment), and scissors (for trimming overlong hoses). If high-precision installation is required, it is recommended to equip a torque wrench to ensure that the tightening force of each clamp is consistent. In addition, prepare a cleaning cloth to wipe the surface of the pipe to remove oil and impurities to avoid affecting the clamping effect.

Q: How to choose the appropriate hose clamp specifications?

A: Seikou hose clamps support a variety of pipe diameters. Before installation, measure the outer diameter of the hose and select the corresponding specifications of the clamp. For example, a hose with a diameter of 10-15mm should match a clamp marked “10-15mm”. If you are not sure, refer to the product manual or contact Seikou customer service for selection suggestions.

2. Detailed installation steps: Four steps to achieve a stable connection

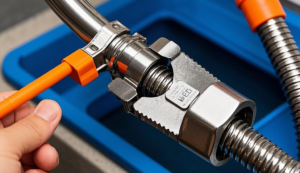

Q: What is the standard installation process of Seikou hose clamps?

A: Follow the four-step method of “positioning – pre-tightening – calibration – tightening”. The specific operations are as follows:

1. Positioning: Put the hose clamp on the connection between the hose and the pipe, and ensure that the center of the clamp is aligned with the interface to avoid offset and uneven force. It is recommended to keep a 5-10mm gap between the clamp and the edge of the interface to prevent extrusion and deformation.

2. Pre-tightening: Use a screwdriver or wrench to lightly tighten the bolts so that the clamp is initially fixed on the hose, but keep a certain amount of space for movement to facilitate subsequent position adjustment.

3. Calibration: Check whether the hose and the pipe are completely aligned and confirm that there is no twisting or folding. If offset is found, loosen the bolts and readjust to ensure smooth pipeline.

4. Tightening: Use a torque wrench to tighten the bolts according to the torque value required by the product manual (such as 1.5-2.5N・m) until the clamp fits the hose tightly. Avoid over-tightening to cause hose damage or clamp deformation.

3. FAQ: Avoiding installation minefields

Q: What should I do if the hose clamp is loose after installation?

A: First check whether it exceeds the applicable pipe diameter range of the hose clamp. If the pipe diameter is too large, you need to replace the clamp with a larger specification. If the specification is correct, it may be that the tightening torque is insufficient, and you can use a torque wrench to tighten it to the standard value. If it is loose multiple times, it is recommended to check whether the bolts are threaded and replace the new clamp if necessary.

Q: How to deal with the installation differences of hoses of different materials?

A: Seikou hose clamps are suitable for a variety of materials such as rubber, PVC, and metal. When installing rubber hoses, the serrated surface of the clamp can enhance friction; when installing metal pipes, it is recommended to add a cushion between the clamp and the pipe to avoid scratching the pipe wall. For thin-walled hoses, the tightening torque needs to be reduced to prevent the pipe from being clamped flat.

Q: Can Seikou hose clamps be reused?

A: Seikou stainless steel hose clamps can be reused provided that the bolts and clamp structures are not damaged. However, after each disassembly, it is necessary to check whether the clamps are deformed and whether the bolts are threaded. If necessary, replace the wearing parts to ensure the reliability of the secondary installation.

4. Seikou Installation Tips: Details Determine Success or Failure

Regular maintenance: It is recommended to check the tightness of the hose clamp every 6 months, especially in high temperature and vibration environments, and tighten the loose clamps in time.

Environmental adaptation: In humid, acidic and alkaline environments, anti-rust oil can be applied after installation to protect the surface of the clamp and extend its service life.

Multiple clamps: For large diameter or high-pressure pipelines, multiple hose clamps can be installed side by side to disperse the pressure and enhance the sealing.

Mastering the correct installation method is the key to unleashing the performance of Seikou hose clamps. From preliminary preparation to installation practice, and then to later maintenance, every link must be treated rigorously. If you still have questions during the installation process, please feel free to contact Seikou’s official technical team. We will provide you with one-on-one professional guidance to ensure that every pipe connection is safe and reliable.