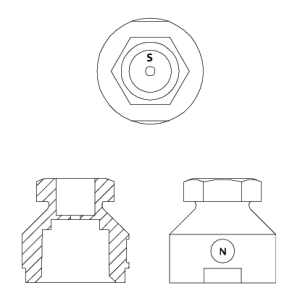

12mm hose clamp with torque cap-Seikou Manufacturer

Material:

Torque cap: Zamak 5 GD-ZnALU Cu1

Surface treatment:

Silver white

Corrosion resistance:

144 hours

Salt spray test (ASTM B-117)

Maximum tightening speed (RPM):

540 ±5

Description

Precise torque control

This 12mm hose clamp is equipped with a torque cap to ensure that the torque applied to the clamp is accurate. When the target torque value is reached, the tip of the torque cap will automatically break off, eliminating the risk of over-torque. This feature ensures that the hose clamp can provide stable and appropriate tightening force every time it is installed, preventing loosening and leakage caused by insufficient torque, and avoiding damage to the hose or the clamp itself due to excessive torque, greatly improving the reliability and stability of the connection, and is suitable for applications with strict requirements on connection strength.

Good material properties

The torque cap is usually made of alloy materials such as Zamak 5 GD – Zn Alu Cu1. This material combines good mechanical properties and process properties. It is strong and easy to process and can withstand a certain degree of external force without deformation or damage. The main part of the hose clamp, if it is made of metal, is mostly made of stainless steel or specially treated steel, which has excellent strength and corrosion resistance; if it is made of plastic, it has the advantages of light weight and good insulation, which can meet the use requirements in different environments.

Excellent corrosion resistance

Verified by salt spray test (such as ASTM B-117 standard), the hose clamp and its torque cap show excellent corrosion resistance at different time lengths. Some products can pass the salt spray test for up to 1000 hours. In a humid and corrosive environment, they can maintain stable performance for a long time, and will not be affected by rust and corrosion. Its fastening function is suitable for pipe connections in harsh environments such as chemical, marine, and outdoor.

Convenient installation and operation

During the installation process, the 12mm pipe diameter has good adaptability and can be easily applied to hoses of corresponding sizes. Its installation method is simple and can be operated with conventional tools. The matching torque cap allows the installer to intuitively judge whether the torque meets the standard. In addition, when the torque needs to be readjusted, the remaining part of the torque cap after breaking can be removed, which is very flexible and greatly improves the efficiency of installation and maintenance.

High tightening reliability

The design of the hose clamp ensures that when tightening, it can form a uniform and stable pressure on the hose, provide a strong clamping force, and effectively prevent the hose from falling off or loosening during operation. Combined with precise torque control, it can always maintain a reliable connection under complex working conditions such as vibration and pressure fluctuations, ensuring the continuous and stable operation of the pipeline system.