8mm American Type Hose Clamp-Seikou Manufacturer

Introducing the 8mm American Hose Clamp, a reliable and efficient solution for all your hose tightening needs. This lightweight clamp is designed to deliver high sealing pressure with an installation torque of only 2.5NM, making it an essential tool for a variety of applications.

|

Material |

W1 |

W2 |

W4 |

W5 |

|

Band |

Zinc plated |

200ss/300ss |

300ss |

316 |

|

Housing |

Zinc plated |

200ss/300ss |

300ss |

316 |

|

Screw |

Zinc plated |

Zinc plated |

300ss |

316 |

|

Bandwidth |

Size |

pcs/bag |

pcs/carton |

carton size(cm) |

|

8mm |

8-12mm |

100 |

2000 |

32*27*13 |

|

8mm |

10-16mm |

100 |

2000 |

38*27*15 |

|

8mm |

14-24mm |

100 |

2000 |

38*27*20 |

|

8mm |

18-28mm |

100 |

2000 |

38*27*24 |

Description

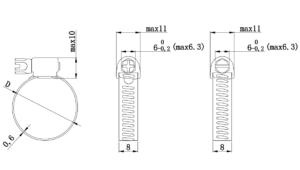

Structural design

Through-hole process: The bite groove on the steel belt is through-hole, and it is formed by hollowing and stamping. There are two types of grooves: rectangular holes and willow leaf holes. The thread of the worm gear screw is embedded in the groove, and the diameter of the throat clamp steel belt is tightened by turning the screw to achieve the locking effect.

Compact size: The 8mm bandwidth belongs to the small American throat clamp, which is small in size and suitable for some occasions with limited space, such as automobile fuel injection control, fuel pipelines, vacuum hoses and other parts.

Material selection

Good corrosion resistance: Commonly used materials are stainless steel (201/304/316) and carbon steel surface plated with white zinc. Stainless steel throat clamps have good corrosion resistance and can be used in harsh environments such as humidity, acid and alkali. They are suitable for occasions with high anti-corrosion requirements, such as outdoor pipelines, chemical machinery, etc.; carbon steel plated with white zinc has a certain rust resistance and can be used in places with relatively low corrosion resistance requirements and strict cost control.

Performance characteristics

Easy to operate: The screw adopts an external hexagonal head with a cross or flat-blade screwdriver in the middle for corresponding tightening. It is easy to operate and can be quickly tightened or loosened, which improves the efficiency of installation and disassembly, facilitates the maintenance and replacement of pipe fittings, and is especially suitable for large-scale assembly processes.

Precise bite: Due to the cooperation between the steel belt bite groove and the screw teeth, it is more powerful when locking, and the tightening degree can be accurately controlled, making the pipeline connection more firmly sealed, which can effectively prevent liquid or gas leakage.

Even stress: The design is precise and the twisting is smooth, which can evenly distribute the stress on the pipe clamp to avoid damage to the pipeline caused by excessive local stress, and also help to extend the service life of the throat clamp and the pipeline.

Wide adjustment range: It is suitable for the connection of soft and hard pipes within a certain size range, which can meet the needs of different pipe diameters, and can usually be used for pipe connections above 30mm.

Appearance characteristics

Beautiful and generous: The overall shape of the product is simple, and the appearance after assembly is beautiful. It is suitable for equipment or places with certain requirements for appearance, such as pipeline connections of high- and medium-range models or some anti-corrosion material parts that need to maintain a good appearance.

However, the 8mm American hose clamp also has some limitations. Since the steel band is permeable, it is easy to break when the tension is strong. The tensile performance is weaker than that of some other types of hose clamps such as German hose clamps, and it is generally not suitable for occasions with extremely high tension.