Clip Clamp-Seikou Manufacturer

Material:

Stainless steel (X5CrNi18/10)

AISI 304

Surface treatment:

Stainless steel

Corrosion resistance:

400 hours

Salt spray (ASTM B-117)

Description

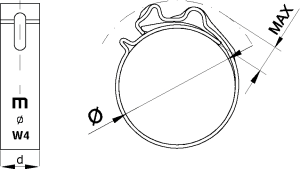

Precise size adaptation

Clip Clamp has a wide range of precise size specifications. In terms of pipe diameter adaptation range, from extremely thin pipe diameters of a few millimeters to larger industrial pipe diameters, there are corresponding products to choose from. For example, for small fuel pipes, vacuum pipes, etc., there are spring clamp styles that are suitable for pipe diameters of 5mm – 5.5mm, and their inner diameters are precisely controlled at 5mm to ensure a tight fit with the pipe. In the industrial pipe connection scenario, products that meet DIN standards cover pipe diameters from DN10 to DN150, and from 12.7mm to 154.4mm under ISO standards, fully meeting the diverse needs of different industries for pipe sizes.

Various material structures

Metal material

Stainless steel: Clip Clamp made of stainless steel is known for its excellent rust and corrosion resistance. This type of clamp is widely used in industries such as chemicals, food and beverages, and medical care. In the chemical industry, stainless steel clips will not be corroded by contact with corrosive chemical media, thus ensuring the sealing and stability of pipeline connections; in the food and beverage industry, its hygiene and corrosion resistance ensure that it will not cause pollution to the product; in the field of medical equipment, due to its stable chemical properties, it will not rust in a complex medical environment, affecting the normal operation of the equipment.

Carbon steel and alloy: Some Clip Clamps are made of carbon steel, and their corrosion resistance is enhanced through surface treatment processes such as galvanizing and chrome plating. At the same time, some high-end products are made of alloy materials, such as zinc alloy for specific models, which improves the durability of the clip while ensuring strength. This material is widely used in general industries, construction and other fields where cost and performance are comprehensively considered. It can withstand a certain strength of external force and will not rust and damage quickly under normal conditions.

Plastic material

Engineering plastics such as nylon: Clip Clamps made of engineering plastics such as nylon have the advantages of light weight, good insulation and low cost. In the electronics and electrical industry, when used to fix cables, it can effectively prevent friction between cables, and due to its insulation properties, it can avoid the risk of electrical short circuits; in some equipment that requires weight, plastic clips can reduce the overall weight and reduce energy consumption; in the field of civilian products, its lower cost advantage makes the product more competitive in the market.

Convenient installation and operation

The design of Clip Clamp fully considers the convenience of installation. Most clips can be installed without complex tools and professional skills. For example, the spring clamp type only needs to use simple tools (or even bare hands) to open the opening of the clip and put it on the pipe. After loosening, the clip can fit the pipe tightly with its own elasticity to achieve rapid tightening. Although screw-fastening clips require tools such as screwdrivers, they are generally designed with a simple bolt and nut structure and are easy to operate. In addition, some clips use a special crimping design to reduce the number of bolts, further simplify the installation process, greatly shorten the installation time, and improve work efficiency.

Stable and reliable connection

High tightening force: Clip Clamp can provide strong tightening force to ensure a stable pipe connection. When industrial pipelines transport high-pressure gases and liquids, the clamps can withstand greater pressure to prevent the pipe connections from loosening and falling off. For example, in the pipe connections of some heavy industrial equipment, the high-strength structural design of the clamps can withstand pressures of up to 5-68MPa, ensuring the safe and stable operation of the equipment.

Excellent sealing performance: Many Clip Clamps are equipped with special sealing gaskets, such as C-type gaskets, which can achieve triple leakage prevention functions. In scenarios involving liquid and gas transportation, it can effectively prevent medium leakage, avoid resource waste and environmental pollution. For example, in the fuel line connection of a car engine, good sealing performance ensures efficient fuel transportation while preventing fuel leakage from causing safety hazards.

Good adaptability

Temperature adaptability: Clip Clamp can adapt to a wide temperature range. In high temperature environments, such as pipe connections near industrial furnaces, metal clips can withstand high temperatures without softening or deforming, and continue to maintain fastening performance; in low temperature environments, such as cold chain logistics pipeline systems, both metal and plastic clips can maintain good flexibility and mechanical properties, and will not become brittle and break due to low temperatures, ensuring that the pipeline system can operate stably under different temperature conditions.

Vibration reduction and noise reduction: In terms of structural design, some Clip Clamps can effectively cut off the noise and vibration transmission caused by the flow of media in the pipeline or the vibration of the equipment by reserving a certain space at the end. At the same time, the sealing gasket can also play a certain role in vibration reduction and noise reduction, reduce pipeline wear caused by vibration, and extend the service life of the pipeline. It is suitable for environments with high requirements for noise and equipment stability, such as pipeline systems in hospitals, precision instrument manufacturing workshops, etc.