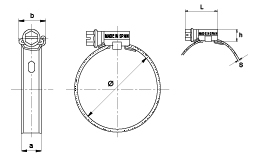

Hose Clamp with Anti-Rotation Hole-Seikou Manufacturers

Material:

AISI-430 stainless steel

Surface treatment:

Stainless steel

Corrosion resistance:

200 hours salt spray test (ASTM B-117)

Maximum tightening speed (RPM):

540 ±5

Description

Exquisite structural design

The hose clamp with anti-rotation hole has a unique anti-rotation hole structure based on the conventional clamp. The hole position is precisely designed and is usually located in a specific part of the clamp body, which is adapted to the clamped hose and the installation environment, providing a hardware foundation to prevent the clamp from rotating unnecessarily during operation.

Excellent anti-rotation function

This core feature gives the hose clamp stability. Under complex working conditions such as vibration and pressure fluctuations, the anti-rotation hole can be used with the matching fixing device (such as bolts, pins, etc.) to firmly fix the clamp in the installation position, effectively avoiding loosening and sealing failure caused by rotation, and ensuring the sealing and reliability of the hose connection.

Convenient and efficient installation

The anti-rotation hole design not only does not increase the difficulty of installation, but also improves the installation efficiency. The installer can quickly find the installation position of the clamp with the help of the anti-rotation hole. After accurate positioning, the existing tools and fixing accessories can be used to complete the installation directly, reducing the adjustment time during the installation process, which is especially suitable for large-scale installation operations.

Various materials

In order to meet the needs of different application scenarios, the hose clamp with anti-rotation hole is made of a variety of materials. Common materials include stainless steel, which has excellent corrosion resistance and is suitable for harsh environments such as moisture, acid and alkali. Carbon steel can also provide good strength and durability after surface treatment and performs stably in general industrial environments. The diverse material selection allows users to flexibly choose according to actual working conditions.