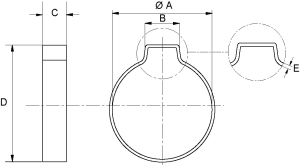

One Ear Clip-Seikou Manufacturer

Material:

Steel ST4 S/DIN 1624

Surface treatment:

Silver white Cr3 zinc plating

Corrosion resistance:

72 hours

Salt spray (ASTM B-117)

Description

Analysis of the product characteristics of the single-ear clamp

1. Structural design

(1) Unique single-ear structure

The single-ear clamp bids farewell to the traditional bilateral symmetrical layout and adopts a pioneering single-sided clamping structure. This design is like a “subtraction revolution” for the installation process, greatly simplifying the operation steps. In a cramped working environment, such as the intricate and crisscrossing “jungle” of pipelines in the engine compartment of a car, or the compact pipeline layout inside a large equipment, the staff only needs to operate flexibly with one hand to quickly and accurately complete the fixation of a specific hose in a limited space. There is no need to go through the trouble of bilateral installation space limitations like traditional clamps, nor do you have to worry about the balance problem of installation on both sides. The single-ear clamp, with its unique structure, makes installation work easy and efficient, greatly improving the overall work efficiency.

(2) Precision adjustable clamping mechanism

The clamping part, as the key “focus point” of the single-ear clamp, is equipped with a set of precision adjustment devices. This set of devices is like a skilled craftsman who can flexibly and accurately adapt to hoses of different diameters. The user only needs to gently rotate the adjustment knob or skillfully slide the adjustment component to achieve extremely fine adjustments to the spacing of the clamps. From small precision hoses of a few millimeters to large industrial pipes of tens of millimeters, the single-ear clamp can easily cope with it, like an all-purpose “master of adaptation”. No matter what diameter of hose, it can fit tightly, provide it with a stable and reliable clamping force, effectively eliminate potential risks such as loose clamping and medium leakage caused by differences in pipe diameter, and ensure that the pipeline system is always in a safe and stable operating state.

2. Material selection

(1) High-strength main material casts a solid “skeleton”

The main part of the single-ear clamp is made of high-quality alloy material, which is like building an indestructible “skeleton” for it. Among them, aviation-grade aluminum alloy material stands out with its excellent lightweight characteristics. In some application scenarios that are extremely sensitive to weight, such as pipeline connections of aerial work equipment, or compact pipeline systems of mobile equipment, the single-ear clamp made of aluminum alloy can greatly reduce the overall weight while ensuring the strength of the clamp, making the equipment more flexible and lightweight, and reducing energy consumption. High-strength stainless steel materials are very effective in the “battlefield” of harsh environments. In the chemical industry, facing various highly corrosive chemical media and the harsh tests of high salinity and high humidity in the marine environment, stainless steel materials, with their excellent corrosion resistance and high strength, effectively resist acid-base corrosion and seawater erosion. Like a loyal guard, they ensure the stable performance of the single-ear clamp under long-term complex working conditions and significantly extend the service life of the product.

(2) Flexible lining materials protect the “skin” of the hose

On the inside of the clamp, in direct contact with the hose, there is a soft and elastic rubber or silicone lining. These flexible materials are like a caring “protective film” and play multiple key roles. On the one hand, they greatly increase the friction with the hose surface, just like putting on a pair of “anti-slip shoes” for the hose, effectively preventing the hose from sliding during the clamping process and ensuring the stability of the clamping. On the other hand, when the clamp applies pressure, the flexible lining can play a good buffering and protective role, preventing the clamp from causing hard scratches on the outer wall of the hose, and gently protecting the “skin” of the hose. Especially for hoses made of soft and easily damaged materials such as rubber and plastic, this layer of flexible lining is indispensable. It ensures that the hose is firmly fixed while maintaining the structural integrity and performance stability of the hose itself to the greatest extent.

3. Clamping performance

(1) Strong and stable clamping force protects pipeline safety

With the unique mechanical structure design, the single-ear clamp can generate a strong and lasting clamping force, like a “steel giant hand” tightly holding the hose. In actual working conditions, even if the pipeline system is facing severe vibrations, such as high-frequency vibrations generated by the operation of engineering machinery and equipment; or there are large fluctuations in pressure, such as pressure fluctuations caused by changes in the flow rate of the medium in the industrial pipeline transportation system; or mechanical shocks, such as bumps and collisions of equipment during transportation, the single-ear clamp can consistently and tightly fix the hose. It ensures the sealing and stability of the pipeline system with a strong clamping force, effectively preventing medium leakage, like a loyal guard, escorting the safety and continuity of the production process, and ensuring that various industrial production activities can proceed smoothly.

(2) Excellent anti-vibration performance to cope with complex working conditions

At the beginning of the design, the single-ear clamp fully took vibration factors into consideration. By cleverly optimizing the structure and carefully selecting high-damping materials, it has excellent anti-vibration performance. In a vibrating environment, the single-ear clamp is like a professional “energy absorption master” that can effectively absorb and disperse vibration energy. When external vibration is transmitted to the single-ear clamp, its unique structure and high-damping materials work together to convert vibration energy into other forms of energy and dissipate it, avoiding loosening of the clamp or fatigue damage of the hose caused by vibration. Taking the fuel pipeline system of a car engine as an example, strong vibration will be generated when the engine is running. The single-ear clamp, with its excellent anti-vibration performance, can always stably clamp the fuel pipeline under such complex working conditions, ensuring the safety and stability of fuel delivery, and providing solid protection for the normal operation of the engine.