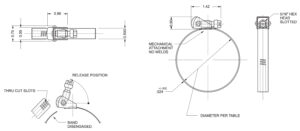

Quick release stainless steel type F clamp-Seikou manufacturer

One-second quick release: One-hand push design, no need to rotate the screw, easily adjust the opening and closing of the clamp, convenient and time-saving operation.

Stainless steel is sturdy and durable: rust-proof and high-temperature resistant, suitable for humid, oily or harsh outdoor environments, and has a long service life.

High-load stable clamping: Strengthen the F-type frame structure, provide 50-300kg clamping force, ensure that the workpiece does not slip or deform.

Multi-function protection design: Adjustable clamp width (50-300mm), with non-slip soft rubber pad to avoid scratching the material surface.

Description

The quick-release stainless steel F-type clamp is an efficient and durable manual clamping tool designed for quick clamping and loosening. It is widely used in woodworking, metal processing, welding, assembly and DIY. Its stainless steel material and F-type structure combine high strength and corrosion resistance, suitable for use in a variety of harsh environments.

Core Features

Quick release mechanism

The clamp opening and closing can be quickly adjusted by pressing or sliding with one hand, without repeatedly rotating the handle, greatly improving work efficiency.

Stainless steel material

Made of 304/316 stainless steel, rust-proof and corrosion-resistant, suitable for humid, high temperature or chemical environments, and prolonging service life.

High load capacity

The reinforced F-type frame design provides stable clamping force (typical load range 50-300kg) to prevent the workpiece from sliding or deforming.

Versatile application

The clamp width is adjustable (commonly 50-300mm) to adapt to workpieces of different thicknesses; the soft rubber pad protection design avoids clamping the material surface.

Typical application scenarios

Woodworking/furniture making: Fixing wooden boards, mortise and tenon structures or glued parts.

Metal welding: Precisely positioning welding parts to reduce thermal deformation.

Mechanical assembly: Temporarily fix parts to facilitate screw tightening or calibration.

DIY repair: Quickly clamp pipes, electronic components or household items.