Seikou-Stainless Steel Round Connector Hose Fittings

Hose Connector Style: Round

Hose connector shape: Ferrule

Material: Stainless steel

Description

Materials and characteristics

Excellent materials: usually high-quality stainless steel materials such as 304, 316 and other stainless steels are used, which have good corrosion resistance, can resist the erosion of various media such as water, oil, acid and alkali, and are suitable for various harsh environments.

Reasonable structural design: adopts a circular design, tight connection, good sealing, and can effectively prevent liquid or gas leakage. At the same time, its structure is sturdy, with high strength and pressure resistance, can withstand certain pressure and tension, and ensure the stability and safety of pipeline connection.

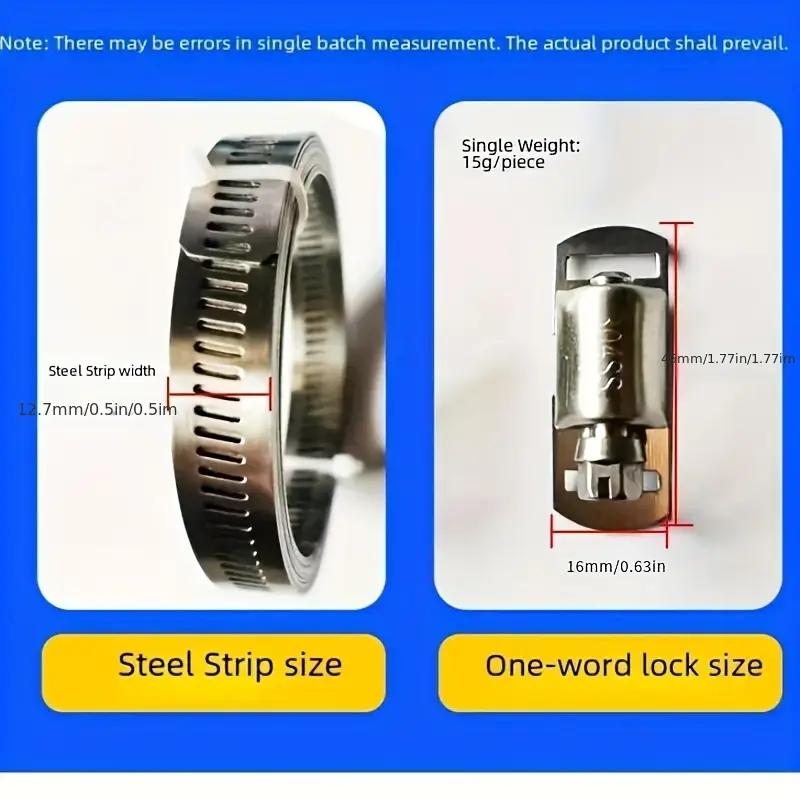

Diverse specifications: According to different application requirements, products of various specifications and sizes can be provided, such as different pipe diameters, lengths, thread specifications, etc., to meet the connection requirements of various pipeline systems.

Application fields

Industrial field: widely used in pipeline systems in chemical, petroleum, natural gas, pharmaceutical, food and beverage industries. For example, in chemical production, it is used to transport various corrosive chemical media; in the oil and gas industry, it is used to connect oil and gas pipelines.

Mechanical manufacturing: commonly used in the hydraulic system and pneumatic system of mechanical equipment, connecting the interface of the hose and the equipment to ensure smooth transmission of hydraulic oil or compressed air.

Automobile manufacturing: This type of accessories is also used in the fuel system, brake system, cooling system and other pipelines of the car to ensure the normal operation of various systems of the car.

Buildings and homes: It is also used in the water supply and drainage systems, heating systems of some buildings, as well as gas pipelines and garden watering pipelines of homes.

Installation and maintenance

Easy installation: It is usually installed by threaded connection, ferrule connection or welding. The installation process is simple and fast, and no special tools and equipment are required. During installation, it is necessary to ensure that the connection parts are clean and free of impurities, the threaded connection must be tightened, the ferrule connection must be clamped, and the welding connection must ensure the welding quality.

Simple maintenance: Regularly check whether the connection parts are loose or leaking. If there is any problem, tighten or replace it in time. At the same time, keep the surface of the accessories clean to avoid pollution and corrosion from the external environment.