Stainless Steel Cable Ties – Seikou Manufacturer

Material:

Stainless steel 304

Surface treatment:

Stainless steel

Corrosion resistance:

400h

Salt spray (ASTM B-117)

Description

Material characteristics

Strong corrosion resistance: Stainless steel materials such as common 304, 316, etc. can effectively resist the erosion of chemicals such as acid, alkali, and salt. It is not easy to rust or corrode in corrosive environments such as humidity, seaside, and chemical industries, and has a long service life.

High strength and load-bearing capacity: It has high tensile strength, can withstand large loads, and is not easy to break. It can be used for pipeline bundling of heavy equipment, fixing of heavy objects, etc., to ensure the safety of the bundled objects.

High temperature and low temperature resistance: It can work normally at extreme temperatures. The high temperature resistance enables it to maintain good physical properties in high temperature environments, and the low temperature resistance enables it to not break due to embrittlement in cold environments. It has a wide range of operating temperatures and can generally work between -80℃~430℃.

Good toughness and elasticity: It has certain elasticity and toughness, can adapt to objects of different shapes and sizes, is more flexible when bundling, can fit tightly to the bundled objects, and will not cause excessive damage to the surface of the objects.

Product Type

Homemade stainless steel cable ties: also known as stainless steel strapping or stainless steel bundling. Users can flexibly cut any length of cable ties according to actual needs. With stainless steel buckles and cable tie tightening machines, they can be quickly installed. They are used to bundle traffic equipment, communication cables, signboards, and pipelines.

Tools Homemade stainless steel cable ties

Steel ball self-locking stainless steel cable ties: small cable ties that use the steel ball locking principle. They are mainly used to bundle cables, signboards, and signs. They are the most widely used type of stainless steel cable ties on the market. Compared with traditional nylon cable ties, they have stronger bundling tension, corrosion resistance, and UV resistance, and have a long service life.

Tools Steel ball self-locking stainless steel cable ties

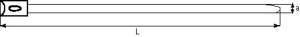

Specifications: Stainless steel cable ties have various specifications. Common widths are 4.6mm, 7.9mm, 10mm, 12mm, 16mm, 19mm, etc. The thickness is generally between 0.25mm-0.76mm, and the length can be customized according to demand in the range of 100mm-2500mm or even longer.

Working principle: The stainless steel belt is fixed together to form a ring through the metal buckle, so as to achieve the purpose of fixing and bundling. When the stainless steel belt is passed through the metal buckle and tightened, the gear or steel ball on the buckle head will lock the belt in the desired position, ensuring a firm connection and preventing the tie from loosening.

Application field

Industrial field: In the power, construction, chemical, machinery manufacturing and other industries, it is often used for cable bundling, pipeline fixing, equipment protection, air duct bundling, etc., and can work effectively in harsh environments to ensure the safe operation of industrial facilities.

Transportation: In automobile manufacturing, it is used to fix on-board equipment, bundle pipelines and cables; on ships, it is used to fix equipment and pipelines to resist sea breeze and salt spray; in the aviation field, it is used to ensure the safe fixation of cables and components inside the aircraft.

Agricultural field: It can be used for the construction of greenhouses, the fixing of irrigation equipment, and the support of crops. Its weather resistance and rust resistance ensure long-term use in outdoor environments.

Daily life at home: It can provide convenient solutions for organizing cables, bundling tools, and fixing items in outdoor activities, which is convenient and practical.