TURBO SEAL Constant Tension Clamp – Seikou Manufacturer

Intelligent constant tension control: Adopting high-precision sensors and servo drive technology, it can achieve tension fluctuation control within ±1%, adapting to high-speed production needs.

Wide compatibility: The modular structure is suitable for a variety of materials (such as PET film, aluminum foil, non-woven fabrics) and industry equipment (printing machines, coating machines, slitting machines, etc.), and supports seamless integration of PLC/automation systems.

Super durability: The core components are made of wear-resistant alloys and precision bearings to ensure long-term stable operation and low maintenance costs.

Intelligent safety protection: Built-in overload protection, material break detection and automatic shutdown functions to reduce material waste and equipment loss.

Description

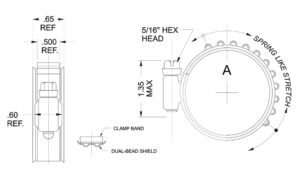

TURBO SEAL constant tension clamp is a high-precision clamping device used in the field of industrial manufacturing. It is mainly used to achieve precise control of material tension in processes such as coil processing, film processing, printing, and coating, ensuring stable material transportation during production and avoiding deformation, breakage or quality problems caused by tension fluctuations.

Core features:

Constant tension control

Through advanced sensors and servo control systems, real-time monitoring and dynamic adjustment of tension ensure that the material maintains constant tension during winding or transmission, which is suitable for scenes with high precision requirements.

Wide application areas

It is mainly used in printing machinery, packaging production lines, lithium battery pole manufacturing, textiles, automotive film coating and other industries, especially suitable for processing thin or highly sensitive materials (such as PET film, aluminum foil, non-woven fabrics, etc.).

Modularity and compatibility

It adopts modular design, can adapt to different mechanical structures, supports integration with PLC or automation systems, and is convenient and quick to install and debug.

High durability

Usually uses wear-resistant materials (such as hardened steel or special coatings) and precision bearings to ensure long-term stable operation and reduce maintenance frequency.

Intelligent feedback and protection

It has abnormal alarm (such as overload, material breakage) and automatic shutdown functions to prevent equipment damage and material waste.

Typical application scenarios:

Printing industry: Prevent paper/film wrinkling or misregistration.

Lithium battery production: Control the uniformity of electrode coating.

Packaging material slitting: Ensure that the slitting edge is flat and burr-free.

Advantage summary:

TURBO SEAL constant tension clamp improves production efficiency and reduces scrap rate through closed-loop control technology. At the same time, its compact design and intelligent operation interface reduce the difficulty of operation. It is suitable for industrial production lines that pursue high precision and high reliability.