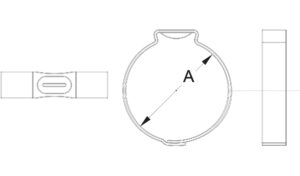

Welded Design Seikou Pinch Clamp

Material:

304 stainless steel (high nickel-chromium content, high temperature resistance up to 800°C)

Surface treatment:

passivation process for rust prevention, surface embossing for anti-skid teeth (enhanced locking stability)

Corrosion resistance:

salt spray test ≥480 hours, resistant to moisture, snow melting agents and industrial corrosion environments

Maximum tightening speed:

professional crimping tools are required, with no speed limit, but they must be operated according to specifications to avoid deformation or sealing failure caused by excessive crimping.

Description

The Welded Design Seikou Pinch Clamp is an industrial clamping device designed for high strength and durability. Here is a brief description of its key features and applications:

Structure and Design

Welding process: The main body adopts a metal welded structure (such as steel or stainless steel) to ensure high load capacity and deformation resistance, suitable for heavy load or high temperature environment.

Clamping mechanism: It may be equipped with mechanical adjustment components (such as screws or levers) to support force adjustment, and some models may have anti-slip grooves/pads to enhance the fixing effect.

Application scenarios

Widely used in pipeline systems, mechanical manufacturing and fields requiring reliable clamping, such as pipeline connection, equipment assembly or production line clamps.

Suitable for high pressure and corrosive environments (depending on the material selection, such as stainless steel for corrosion resistance).

Material and durability

The material is mainly steel or special alloys, and the surface may be plated or painted to improve rust and wear resistance.

Use and maintenance

The clamping force needs to be adjusted according to the specifications to avoid damage to the workpiece; regularly check the integrity of the welding points and the lubrication of the moving parts to ensure long-term stability.

Potential variants

Possible designs such as quick release and safety locks to meet different working conditions.

The clamp is based on a welded reinforced structure, combining strength and adaptability, making it a reliable tool in industrial fixed scenarios. Specific parameters (such as size and load-bearing capacity) need to be further confirmed by referring to the manufacturer’s information.