Wire Clip-Seikou Manufacturer

Material:

Spring steel (DIN 17223-B)

Surface treatment:

Silver white trivalent chromium zinc plating

Corrosion resistance:

72 hours

Salt spray (ASTM B-117)

Description

Common structural types

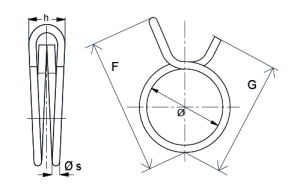

R-type wire clamp hose clamp: The appearance is “R”, the main body is made of metal (such as stainless steel, iron galvanized material), and some products are coated with EPDM rubber, nitrile rubber or silicone on the outer layer. This structure can provide good wrapping for the hose. The metal material ensures strength, and the rubber layer can buffer and reduce shock, protect the outer wall of the hose, and avoid wear. It is often used to fix hoses in automotive wiring harnesses and electrical equipment wiring, such as the fixation of various oil pipes and water pipes in the engine compartment of a car.

U-type wire clamp hose clamp: The shape is similar to “U”, and there are also metal and rubber-coated models. The metal part is mostly made of carbon steel, stainless steel or iron galvanized material, and the rubber is made of aging-resistant and oil-resistant rubber. It is often used to fix multiple parallel hoses at the same time, or in scenes with high requirements for fixing strength, such as ship piping systems and large cooling water pipes of industrial equipment.

P-type wire clamp hose clamp: It is semi-circular “P” shaped, with a single tube clamp design, often equipped with rubber strips, and made of metals such as iron galvanized. It is generally used to fix smaller diameter hoses on flat surfaces or walls, such as gas hoses and small water supply and drainage hoses to walls in building decoration.

Fastening principle: The wire clamp hose clamp mainly relies on the clamping force generated by its own structural deformation to tighten the hose. Taking the common R-type and U-type as examples, the hose is placed in the wire clamp groove during installation, and tightened by bolts, screws and other connectors to gradually tighten the wire clamp and fit tightly with the outer wall of the hose, using friction and clamping force to prevent the hose from moving.

Product features

Diverse materials and strong adaptability: The metal part is made of stainless steel, which has excellent corrosion resistance and is suitable for harsh environments such as humidity, acid and alkali, such as chemical enterprise pipelines; iron galvanized materials are low in cost and meet the general environment use requirements. They are widely used in civil buildings and general industrial equipment. Rubber-coated materials such as EPDM rubber have good weather resistance and can be used outdoors for a long time; nitrile rubber has good oil resistance and is suitable for oily medium pipelines such as fuel and lubricating oil.

Easy installation, efficient and reliable: Most wire clamps and hose clamps have a simple structure. When installing, you only need to put the hose in place and tighten the screws to fix it. It is easy to operate, does not require professional tools and complex technology, and can greatly improve the installation efficiency. And once the installation is completed, the fastening effect is stable and reliable, and it is not easy to loosen.

Rich specifications and wide application: From a few millimeters to tens of millimeters in inner diameter, hoses of different pipe diameters can find suitable wire clamps and hose clamps. This makes it widely used in many fields such as automobile manufacturing, shipbuilding industry, electric power, construction engineering, mechanical equipment, etc. In the automotive industry, it is used to fix engine cooling water pipes, brake oil pipes, etc.; in the construction field, it is used to fix air conditioning refrigerant pipes, fire sprinkler water pipes, etc. .

Performance parameters

Temperature resistance: The temperature resistance range of wire clamps and hose clamps of different materials is different. For example, the static working temperature range of products with stainless steel and EPDM rubber is generally -40℃ to 120℃, and can instantly withstand heat to 150℃ – 200℃, which can meet the temperature requirements of most conventional working conditions; and some products made of special high-temperature resistant materials can withstand higher temperatures and are suitable for special scenarios such as high-temperature steam pipelines.

Bearing capacity: The bearing capacity varies according to the material, structure and size of the wire clamp. Generally, large-sized, high-strength metal wire clamps with reasonable structural design can withstand greater tension and pressure, ensuring the stability of hoses in heavy equipment and high-pressure pipeline systems.

Corrosion resistance: Stainless steel wire clamps have good resistance to various corrosive media due to their alloy characteristics; iron galvanized materials are protected by the surface galvanized layer, which can effectively prevent rust in general environments; and rubber-coated materials can also prevent the metal part from contacting with external corrosive media, further enhancing corrosion resistance.