Seikou factory specific manufacturing inspection

With the goal of “zero defects”, the Seikou factory has built a closed-loop manufacturing inspection system that runs through the…

With the goal of “zero defects”, the Seikou factory has built a closed-loop manufacturing inspection system that runs through the entire product life cycle.

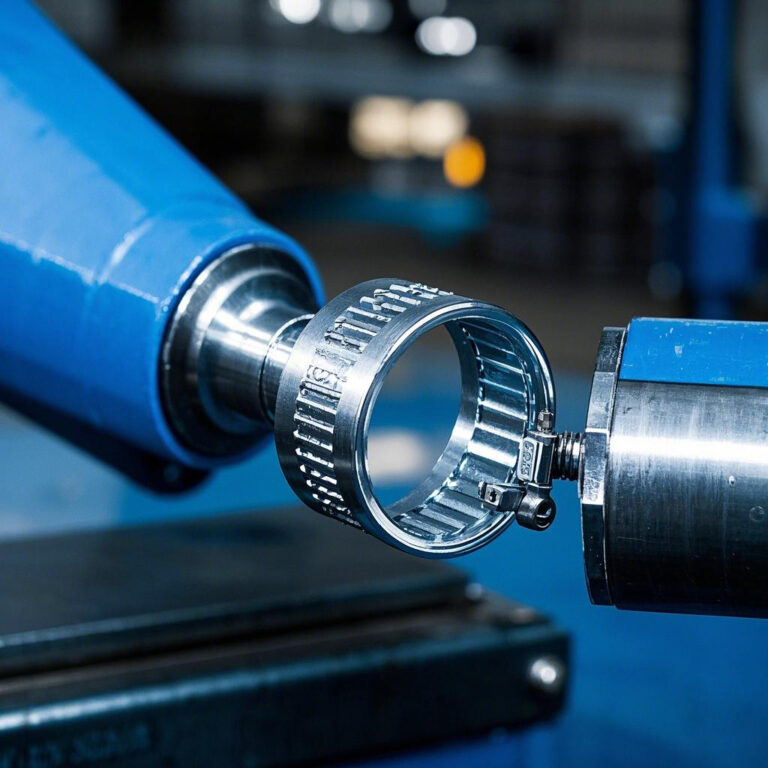

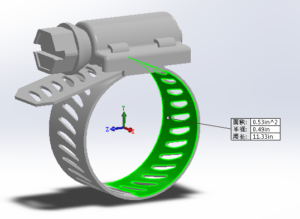

In the production startup phase, the factory adopts a “double verification” mechanism: after the operator completes the debugging of the first product according to the standardized operating instructions, the quality engineer simultaneously performs 16 key indicator tests such as dimensional accuracy and material performance to ensure that the process parameters are absolutely matched with the design specifications.

During the production process, systematic inspections cover key nodes of human-machine interaction, such as recording the temperature fluctuation of CNC equipment every hour, sampling the surface treatment uniformity of products every two hours, and using the AI visual system to compare the good product feature library in real time to achieve millisecond-level abnormal warning.

For high-risk processes (such as precision welding), “dynamic interception points” are added. Any data deviation beyond the control line will automatically trigger the suspension of the production line to avoid the spread of defects. In the batch closed-loop stage, the last product must pass the full project inspection and form a trend analysis report with the first piece of data. At the same time, blockchain technology is used to encrypt and store quality inspection records to ensure that quality data in all links of the supply chain cannot be tampered with.

Through the four-layer defense of “prevention-monitoring-interception-traceability”, the system has reduced the process defect rate of the Seikou factory to below 0.12%. It has passed UL certification and SEDEX social responsibility factory audits for three consecutive years, becoming a benchmark enterprise in high-end manufacturing in the fields of automotive electronics and medical devices.