Troubleshooting: Removing Hose Clamps That Won’t Budge

Encountering a hose clamp that refuses to budge can be frustrating, whether you’re working on automotive repairs, plumbing tasks, or…

Identify the Type of Hose Clamp

Screw Clamps: These are the most widely used, featuring a band with a screw mechanism. You can loosen them using a screwdriver or a nut driver, depending on the screw type.

Spring Clamps: Also known as constant-tension clamps, they rely on a spring to maintain pressure. Special spring clamp pliers are ideal for this type, but a flat-head screwdriver or a pair of regular pliers can also be used in a pinch.

T-Bolt Clamps: Often used in high-pressure applications, they have a T-shaped bolt that requires a socket wrench or an Allen key for adjustment.

Worm Drive Clamps: Similar to screw clamps, they have a worm gear that tightens the band. A flat-head screwdriver is usually sufficient for removal, but rusted ones may need extra effort.

Tools You’ll Need

Pliers: Long-nose pliers, locking pliers (Vise-Grip), or adjustable pliers can help grip and turn stubborn screws or pull clamps free.

Screwdrivers: A set of flat-head and Phillips-head screwdrivers is essential for screw-type clamps. Ensure the tip fits snugly into the screw head to avoid stripping it.

Hose Clamp Pliers: Specifically designed for spring clamps, these pliers compress the spring, allowing you to slide the clamp off the hose easily.

Penetrating Oil: Products like WD-40, PB Blaster, or Liquid Wrench can be applied to rusted or corroded clamps. Let the oil penetrate for 10-15 minutes to loosen the rust and make the clamp easier to turn.

Heat Gun or Torch: For extremely stubborn clamps, applying heat can expand the metal slightly, breaking the bond between the clamp and the hose. Use this method with caution, as excessive heat can damage the hose.

Step-by-Step Removal Techniques

For Screw and Worm Drive Clamps

1.Apply Penetrating Oil: If the clamp is rusted or difficult to turn, spray penetrating oil around the screw or worm gear. Let it sit for at least 10 minutes.

2.Loosen the Screw: Use the appropriate screwdriver or nut driver to turn the screw counterclockwise. If the screw is stripped, try using a screw extractor or pliers to grip the head and turn it.

3.Slide the Clamp Off: Once the screw is loose, slide the clamp along the hose towards the end to remove it completely. If it’s still stuck, gently wiggle the clamp while pulling it off.

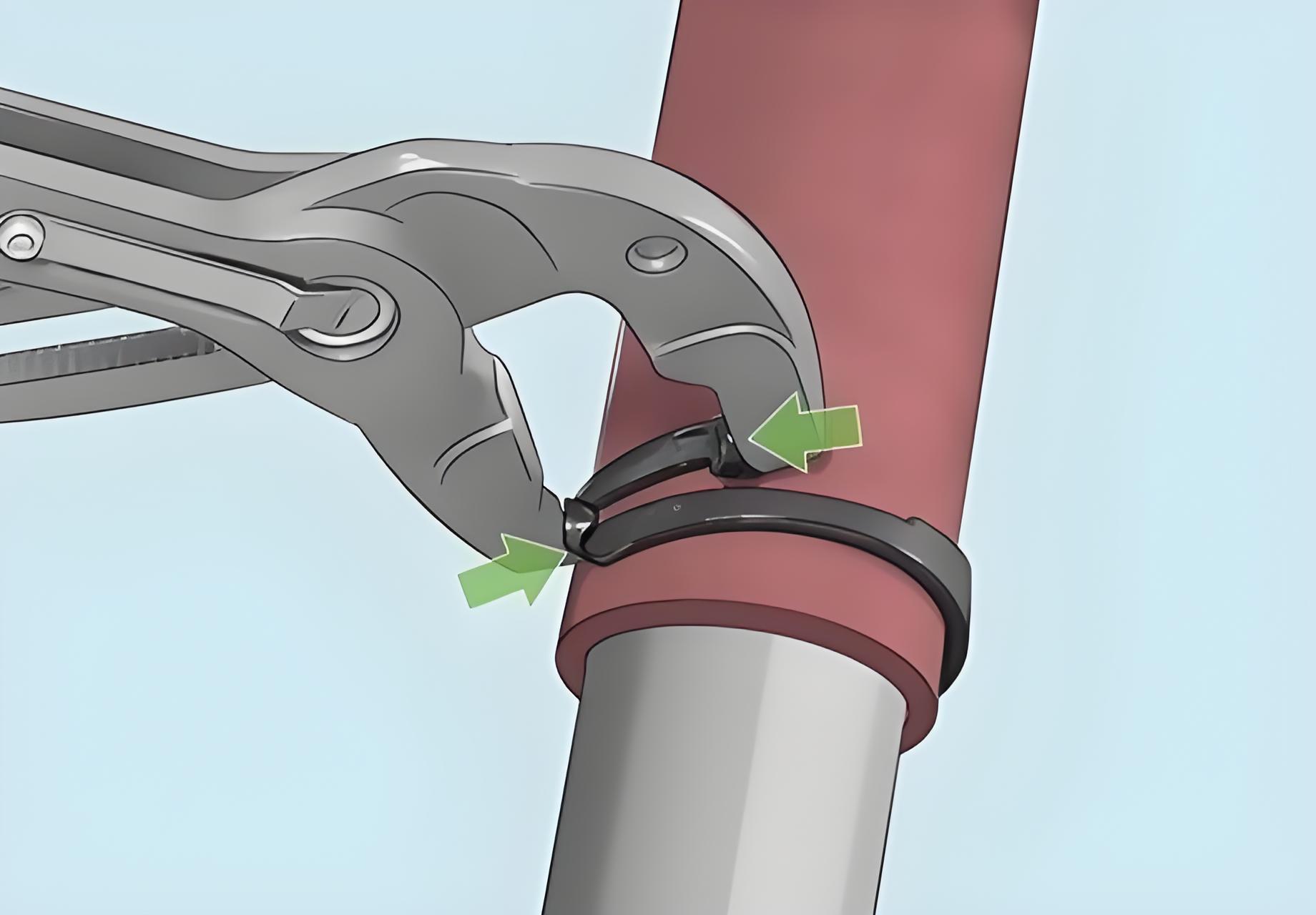

For Spring Clamps

1.Position the Pliers: Place the jaws of the hose clamp pliers on the spring arms of the clamp. Squeeze the pliers to compress the spring, which will release the tension on the hose.

2.Slide the Clamp Off: While holding the pliers, slide the clamp towards the end of the hose. If you don’t have specialized pliers, use a flat-head screwdriver to pry open the spring arms slightly and then pull the clamp off.

For T-Bolt Clamps

1.Use the Right Tool: Select the appropriate socket wrench or Allen key for the T-bolt. Turn the bolt counterclockwise to loosen the clamp.

2.Remove the Clamp: Once the bolt is loose enough, slide the clamp off the hose. If the bolt is seized, apply penetrating oil and let it sit before attempting to turn it again.

Dealing with Extreme Situations

Stripped Screws: If the screw head is stripped, try using a rubber band placed between the screwdriver and the screw head to gain better traction. Another option is to file the top of the screw flat and use a flat-head screwdriver or a chisel to turn it.

Severely Corroded Clamps: In cases where corrosion has fused the clamp to the hose, you may need to carefully cut the clamp with a hacksaw or a Dremel tool. Be extremely cautious not to damage the hose during this process. After removing the clamp, inspect the hose for any signs of wear or damage.

Heat Application: If all else fails, use a heat gun or a torch to warm the clamp gently. Start from a distance and gradually move closer, rotating the heat source to avoid overheating one spot. Once the metal expands slightly, try loosening the clamp again.

Safety Precautions

Wear Protective Gear: Always wear safety glasses, gloves, and appropriate clothing to protect yourself from sharp edges, flying debris, or hot components.

Work in a Well-Ventilated Area: When using penetrating oil or heat, ensure the area is well-ventilated to avoid inhaling harmful fumes.

Disconnect Power Sources: If you’re working on machinery or equipment, make sure to disconnect the power or fuel source to prevent accidents.